Failure isn’t an option when managing critical facilities. Preventing failure is one of your primary responsibilities, which you ensure with a robust design, plenty of backup systems and extremely well managed operations. This applies to obvious facilities such as data centers, but also to facilities such as manufacturing, hospitals and other high reliability operations.

Managing the performance of the Facility Management function in this environment is key to minimizing your risk.

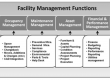

Your tools include proactive performance management and reporting, quality management, effective interfaces with the managers of the critical operations and strict processes and procedures for maintenance and repair activity, with well defined interfaces.

Think of your facility as a jumbo jet, essentially a complex flying facility with 100% up-time requirements. On your next flight, how safe would you feel if the pilots didn’t have instrumentation? What if all they had was the small forward looking window? What if instead of a flight manual and checklist, all they had was their memory? That’s what managing a critical facility is without effective performance management tools.

These tools are typically applied to an outsourced arrangement, but the principles should also be applied to individual subcontracted services and your own in-house services.

Performance Measurements in Critical Facilities

Managing performance in critical facilities isn’t just introducing Key Performance Indicators (KPI’s), tracking results periodically and penalizing failure. Especially with critical facilities where failure isn’t an option. The risks are too great and KPI’s are really only part of the overall approach to getting results and eliminating failure. Rather than looking in the rear view mirror, you need to be looking forward.

Start with an integrated contract management approach that works with your service providers to achieve joint success. It includes performance measurements that address current performance while providing forward looking trends and measurements that are analyzed and acted upon proactively.

It also includes some form of service level definitions which clarify the responsibilities and documents the extent to which the service is performed and expected. This is key whether you are hiring contractors or staffing-up internally.

A Quality Assurance approach should govern the processes and service delivery. Whether ISO certified or not, a quality program provides consistency and monitors adherence to effective procedures and practices.

Finally, effective procedures and policies that seek to limit the possibility of failure must be put in place. These include traditional ticketing and change notification processes used in the IT industry – extended and adapted to the maintenance and operations function in-house or outsourced.

Contract Management

For outsourced Facility Management services, your contract document is an important tool throughout the term of the contract, however your approach to managing the contract is just as important.

Your service provider has a vested interest in success, just like your organization. A constructive approach to managing the contract is key to establishing a relationship where the service provider understands and addresses your needs without always checking the contract. If you are inflexible, they will be inflexible. If you want flexibility, you need to manage the contract relationship accordingly.

The contract language itself must be flexible and enable you to adjust priorities, address issues and make changes that you need to be successful through the full term in a constructive, planned manner. While your procurement department will likely be responsible for the contract documentation, make sure it has flexibility built in that suits your ongoing management needs in addition to having the standard contractual, legal and risk clauses. This will enable you to effectively manage the contract beyond start-up.

The contract for managing critical facilities must include provisions for performance management, including the ability to adjust or change the measures and targets to adapt to your changing priorities.

Effective interface, communication, reporting and processes must be spelled out in the contract, with structured meetings that support your contract management approach and forward looking management.

The contract and related specifications, as well as the procurement process, must define the responsibilities and processes for the transition-in at the start of the contract as well as transition-out at the end of the term to a different supplier. Just like takeoff and landing for a jumbo jet, these are among the most risky periods in a contract cycle, particularly for management of critical facilities. The key issue of personnel and training / knowledge transfer during a transition is one issue that needs to be addressed.

Identifying key expectations such as risk assessment and mitigation are also important. By identifying these responsibilities, you clearly indicate their importance and add their skills, knowledge and on-site experience to your overall risk management initiatives.

Proactive Performance Management

Effective management uses a proactive approach, not just the typical static measurements. Rather than simply reporting measurements such as call response time, maintenance backlog, temperatures and similar key measures against targets and penalizing the supplier, the information must be used to manage future performance, with trending and analysis by the service provider.

This provides critical advance warning when services, systems or processes are trending towards a failure and enables the service provider to correct them before they fail. Managing performance this way is more effective than the carrot and stick approach. Remember, you will be accountable for shutting down your organization’s core business no matter who was responsible.

For critical facilities, measurements extend to key aspects of the system where trends and other management information are used to prevent failure. Frequently, equipment performance such as current draw is recorded during preventive maintenance tasks, however this information is seldom compared to historical readings to see trends and initiate action. In a critical facility, this should be part of the overall management approach.

Other examples include temperature in equipment cabinets for a data center facility, humidity in a printing facility or biomedical refrigerators in a hospital. These may be alarmed and even measured for supplier performance if they go outside a specified range, however they also should be trended and more importantly, analyzed. If temperatures, frequently rise to just below a critical threshold but don’t exceeding them, this indicates a performance problem that is likely to create a failure in the future. It is better to assess the root cause and fix it now than waiting for the high temperature alarm.

Even if you use measures to penalize your supplier, require them to investigate and report on causes and initiate corrective action for measures that are within a certain tolerance but don’t exceed the targets.. Instead of penalizing for non-performance on non-critical items, give them a chance to assess and rectify the performance first. This creates a better relationship and gets you better results. If their action plan is not successfully implemented or the issues are recurring, a penalty could then be applied.

For management purposes, include measures that predict reliability or potential performance issues. By requiring analysis and a corrective action plan as described above, you improve the likelihood of succeed rather than simply penalizing failure.

For existing facilities, be careful about penalizing the service provider if it relates directly to the reliability of existing equipment and lack of redundancy. In these cases, assess their activities against expectations (such as adhering to process, response to issues and failures, preventive maintenance completion rates, identifying risk, etc.). By implementing proactive performance management, you are in a better position to mitigate the inherent risks.

One way to implement total accountability is to include the ongoing facility management function as part of a new design/build initiative where the contract includes providing FM services for a lengthy term beyond the initial construction. This can also include infrastructure renewal/replacement. This technique provides full accountability for performance from end to end.

Service Level Definitions

Service Level Definitions define expectations, technical service specifications, and performance requirements. They are similar to contract specifications, however instead of providing highly prescriptive task based requirements, they shift the focus to a results based specification where possible. This gives the service provider latitude to use their own skills, technology and knowledge to adjust the service and achieve the results rather than having to adhere to prescriptive specifications.

There are areas where detailed technical specifications are necessary. These are also an important tool for the service provider to properly staff and price the service (for instance, specifying predictive maintenance activities above and beyond traditional preventive maintenance tasks), however a shift to results based specifications will get better results when combined with effective contract management and performance management techniques.

Quality Management

A key responsibility of the Facility Management service is to prevent failure in a critical facility and ensure the company’s core business isn’t negatively impacted.

Implementing Quality Management principles provide an additional measure of protection against failure when implemented and used effectively. Even if you don’t require ISO certification, implement a Quality Management system that is rigorous and follows the same principles.

Quality Management systems themselves don’t ensure quality, they ensure that quality processes are put in place and used consistently. As a result, effective processes and procedures are the key to achieving quality. Your quality management system uses checks and balances, including auditing and testing, to ensure that the processes and procedures you or your service provider have in place are consistently used as intended.

A good Quality Management system includes a process to identify changes that should be made to processes and procedures and enables flexibility.

Process and Procedures

The best intentions with managing performance, contract management techniques or quality management initiatives will fail if appropriate procedures and processes are not in place to mitigate issues and reduce potential failure.

For critical facilities, build these into the contract by focusing on potential failure points and addressing them up-front. If you don’t have them in place already, develop them in conjunction with your service provider or with your own staff.

Integrate the FM maintenance and operations processes with the core business operations at the facility. The best examples are the processes used by IT professionals to deal with change and issues management within their own systems and infrastructure. Whether you use their processes or a parallel system, integration is critical to ensure communication, planning and approval so activities such as preventive maintenance and repair, for instance, don’t negatively affect the core business. As an example, if an activity introduces risk, such as taking a backup system off-line, alternative backup or processes to quickly rectify failure during the work activity should be identified and planned as part of the process.

This planning and approval process is critical. For instance, within a hospital, maintenance activities can have a serious impact if not planned accordingly, so hospital representatives are given advance schedules of activities, along with an assessment of potential risks and plans to mitigate the risk. The hospital representative can request changes to the schedule or modify work activities to suit hospital needs and schedules. You reduce the chance that a seemingly minor activity will compromise the hospital’s critical clinical and patient related activities.

You may notice that effective communications and a good contract management relationship is the main themes of the performance management approach at critical facilities. Since human error is responsible for the majority of failures, implementing this performance management approach in your critical facility can improve your chance to succeed and minimize your risk.